Respirable Crystalline Silica in the UK: are you protected from the dangers of silica dust?

September appointments are available for Mobile (on-site) Chest X-Ray services – book your spot now!

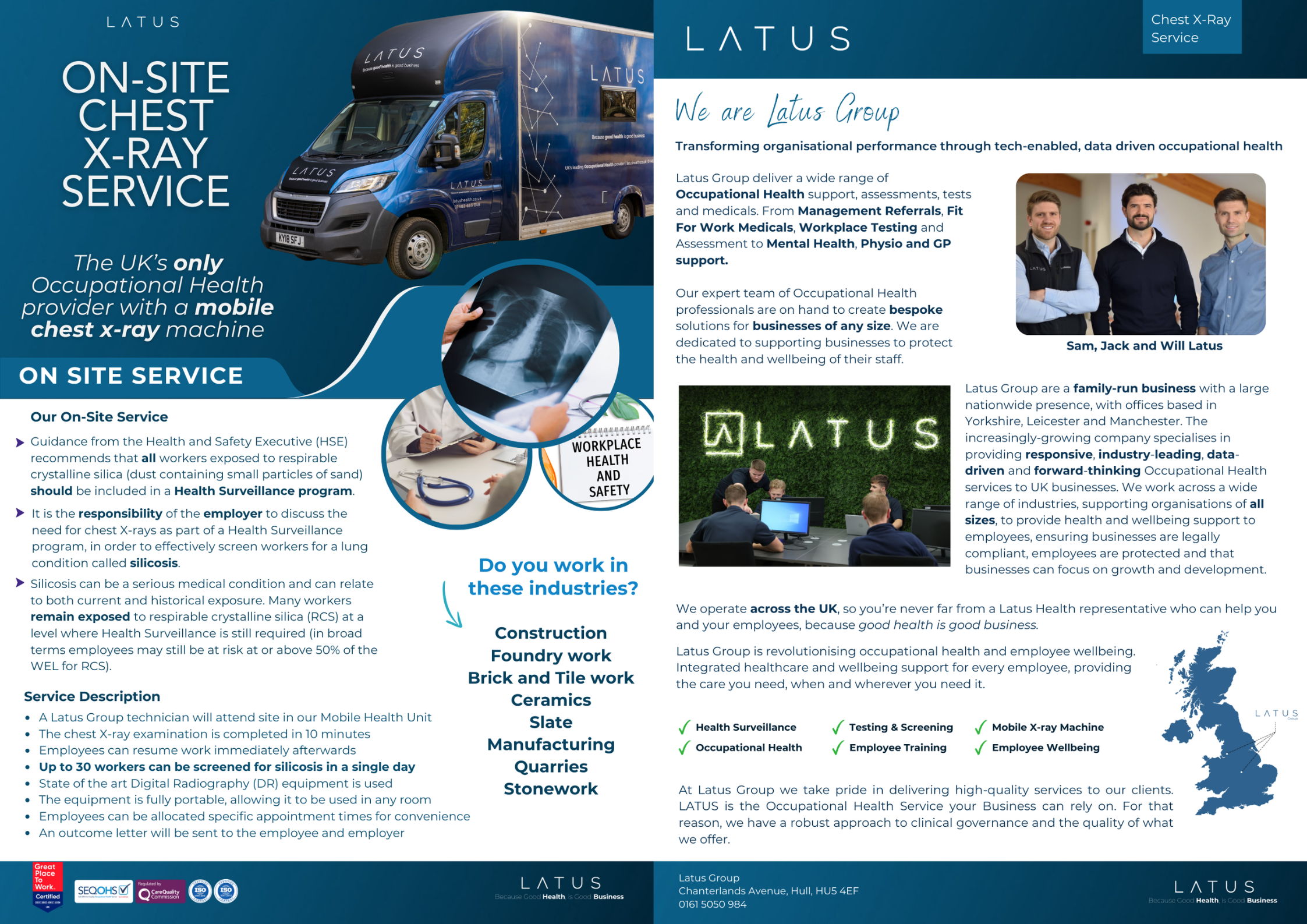

Health Surveillance vs Occupational Health. Do you know the difference? Latus Group, a leading provider of occupational health in the UK, is offering a vital solution with its mobile chest X-ray service, helping companies proactively screen workers exposed to silica dust.

Crystalline Silica dust, a common yet invisible hazard, poses a serious threat to the lungs of many workers across various industries.

Crystalline Silica is a naturally occuring mineral found in many rocks, sands and soils in different forms such as quartz, tridymite and cristobalite. These products are commonly used in manufacturing, construction, quarrying and related industries.

Silica becomes dangerous when these tiny particles, which are undetectable to the naked eye, are inhaled.

Any industry which requires a form of fracturing a silica product and generating dust, or which are confined to low-ventilated areas around these minerals, are vulnerable to the harmful effects of Respirable Crystalline Silica (RCS)

Prolonged inhalation of silica dust can lead to a debilitating and incurable lung disease called silicosis, alongside other serious health conditions such as lung cancer.

Health Surveillance vs Occupational Health: Understanding the Dangers of Crystalline Silica

Silicosis is the most common occupational lung disease worldwide and is the condition most strongly associated with exposure to silica.

Activities like sandblasting, drilling and cutting concrete generate respirable silica dust particles, so small they can enter deep into the lungs.. Over time, the body struggles to remove these particles, leading to inflammation and scarring.

This scarring process, known as silicosis, progressively reduces lung function, causing shortness of breath, debilitating coughs and chest tightness.

The higher the exposure, the shorter the latency and the faster the disease spreads.

Acute silicosis is when a person has had extremely high exposure over a short period of time and can lead to fatality within months, however the more common condition is chronic silicosis. This occurs when a person has been subjected to ongoing, low-level exposure.

Industries at Risk and Recent Statistics

Crystalline Silica dust is classified as a carcinogen, meaning it can cause lung cancer.

Construction workers, sandblasters, miners, foundry workers and anyone involved in grinding or processing stone products are particularly at risk, with the HSE estimating around half a million people in the UK are exposed to silica dust in their work.

Silicosis often develops slowly, with symptoms appearing years after initial exposure. Early detection is crucial for managing the disease and preventing further complications. While there is no cure for silicosis, early diagnosis allows for treatment of symptoms and monitoring of lung function to improve quality of life.

Health Surveillance vs Occupational Health: which one do my workers need?

The Health and Safety Executive (HSE) have enforced limitations for what an individual’s personal exposure to RCS can be within a working day.

The HSE states, “Health Surveillance should be considered for workers who are involved in high-risk occupations, including construction, foundry work, brick and tile work, ceramics, slate, maufacturing, quarries and stonework. Where workers are regularly exposed to RCS dust and there is a reasonable likelihood that silicosis may develop, Health Surveillance must be provided”

The current Workplace Exposure Limit (WEL) is 0.1mg per cubic metre over a Time Weighted Allowance (TWA) of 8 hours, and a Maximum Exposure Limit (MEL) of 0.3mg per cubic metre.

The Control of Substances Hazardous to Health (COSHH) Regulations provides guidance for employers on how to assess and control exposure to hazardous substances, including silica dust.

So how can businesses ensure they are compliant with UK Health Standards?

- Elimination or substitution: the first thing to consider is if silica products, or dust generation can be removed from the process

- Control measures: examples of reducing the potency of RCS includes automating, isolating or enclosing the process. Where possible, ventilation systems should be utilised, as should wet cleaning and cutting metholds.

- Administrative controls: Update work practices or policies to reduce individual exposure to RCS. Use staff rotation and establish work schedules to minimise the amount of time individual workers are exposed for. The provision of training and education is also considered an administrative control.

- Health Surveillance: including lung capacity checks should also be carried out on a regular basis.

- PPE: if exposure is still high, adequate Respiratory Protective Equipment (RPE) should be provided.

Latus Group’s Mobile Chest X-ray: a convenient and effective screening tool

Latus Group provide a mobile, on-site chest X-ray service that fully aligns employers with this recent updated guidance from the HSE, enabling them to demonstrate good working practice.

By implementing regular mobile chest X-ray screenings, companies can proactively protect their workforce from the devastating effects of crystalline silica dust. Early detection allows for treatment interventions and ensures workers are aware of the risks associated with their jobs.

Latus Group’s mobile solution empowers businesses to prioritise worker health and safety, creating a healthier work environment for all.

Service Description

Latus Group will attend site on a day convenient to the business and deliver a chest X-ray service against shift patterns of employees.

The entire chest X-ray examination is completed within 10 minutes and employees are able to return to their normal activities immediately. Up to 30 workers can be screened for silicosis in a single day.

State of the art Digital Radiography (DR) equipment is used; this gives a very high resolution image which is a very effective screen for silicosis or other occupational lung disease. Furthermore, the equipment used delivers very low doses of radiation and the risk is therefore extremely low.

The equipment is fully portable, allowing the chest X-rays to be taken in a suitable room on-site. We will ensure the room is suitable through a risk assessment process.

Employees can be allocated specific appointment times for their chest X-ray against a schedule that we will provide. Site disruption and lost operational time is therefore minimal, particularly in comparison to hospital based provision which includes travel time and cost as well as wait times in out-patient departments.

Once the chest X-rays have been taken, read and reported on, an outcome letter will be sent to the employee and employer. The letter will advise on the results of the chest X-ray and the appropriate action regarding continued participation in statutory Health Surveillance, including the chest X-ray program.